There are seven different types of hydraulic pumps. They are listed and defined below.

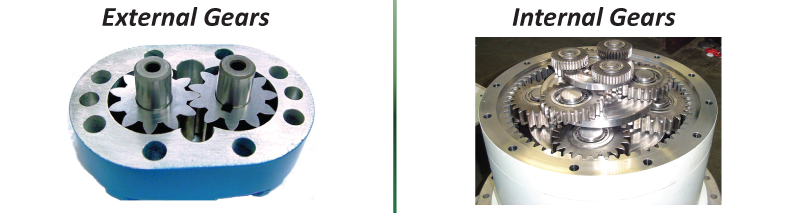

Gear Pumps: There are external and internal gear pumps. Both pump fluids using displacement. External gear pumps have two separate spur gears that work by interlocking the teeth of each gear to cause rotation. Internal gear pumps work by having a large gear with internal teeth containing a smaller gear with outward facing teeth that interlock to cause rotation. Fluid fills the void in the gear rotation on the inlet side of the valve creating suction. The fluid is then rotated and displaced to the outlet side of the pump where the teeth and void meet.

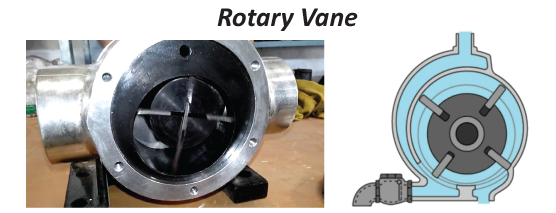

Rotary Vane Pumps: These consist of a circular cavity that contains an offset circular rotor. The rotor has multiple stationary vanes leading off that fit snugly to the cylinder walls. The inlet valve allows fluid to fill the cavity. Rotation of the rotor moves the fluid to the outlet valve causing suction to bring fluid into the next available cavity.

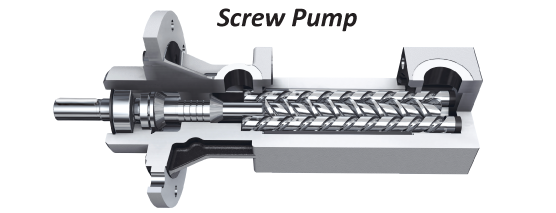

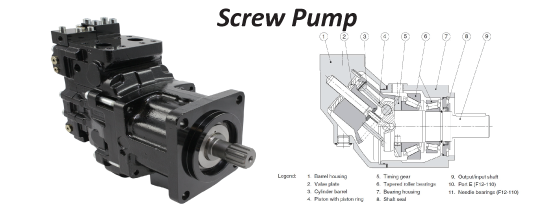

Screw Pumps: This pump houses two Archimedes screws that interlock inside an enclosed chamber. Fluid is pumped from the inlet to the screws where it is moved down the spindles and forced through the outlet opening. These pumps can utilize one or multiple screws inside the housing.

Bent Axis Pumps: Pistons inside of a rotating cylinder are attached to a rotating angled plate with rods. The angle of the plate causes half of the pistons to suck fluid into a cavity as rotation occurs the rods compress the piston along with the fluid forcing it through the outlet.

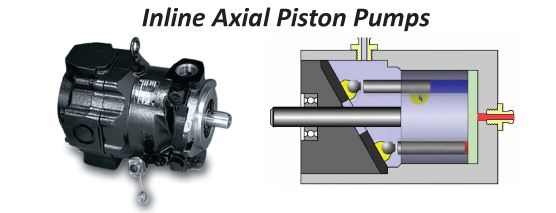

Inline Axial Piston Pumps: Pistons contained in a cylindrical housing block rotate on an axis with a fixed angled plate. As the unit rotates the plate orientation withdraws the piston causing fluid to fill the empty cavity from the inlet valve. Rotation on the axis presses the plate down on the piston extruding the fluid through the outlet valve.

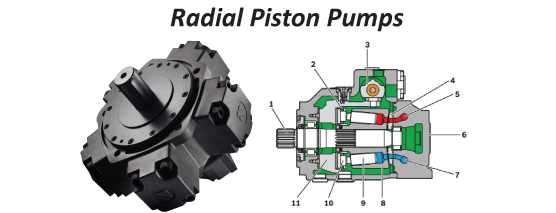

Radial Piston Pumps: Pistons are arranged around an interior rotor. Each piston is attached to a spring loaded inlet and outlet valve. These valves are attached to a single exterior inlet and outlet valve. As the rotor rotates it causes the pistons to either intake fluid or discharge fluid. This is commonly used in drive shafts of vehicles.

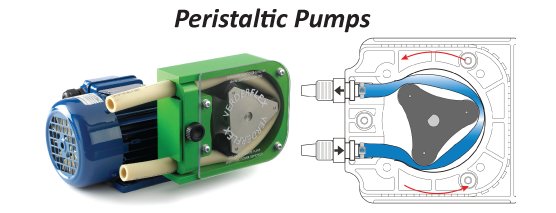

Peristaltic Pumps: A flexible tube is attached to an inlet and outlet valve. This tube is set in a “U” shape along the housing wall. A rotor with shoes or rollers on two sides is placed inside of the “U”. As the rotor spins it pinches the tube shut. As it rotates the fluid contained in the tube is forced forward by the roller and eventually exists the outlet.